KR has successfully completed a feasibility study for the conversion of an 8,600 teu containership into a 10,000 teu vessel for one of its customers.

This new capacity specification was developed in response to a shipping company’s desire to adapt to recent shipping environment changes and to improve operational efficiency. In recent years a change in the optimal size of vessels and a deterioration in the operational efficiency of existing ships, has led to newbuilding orders or the conversion of existing ships.

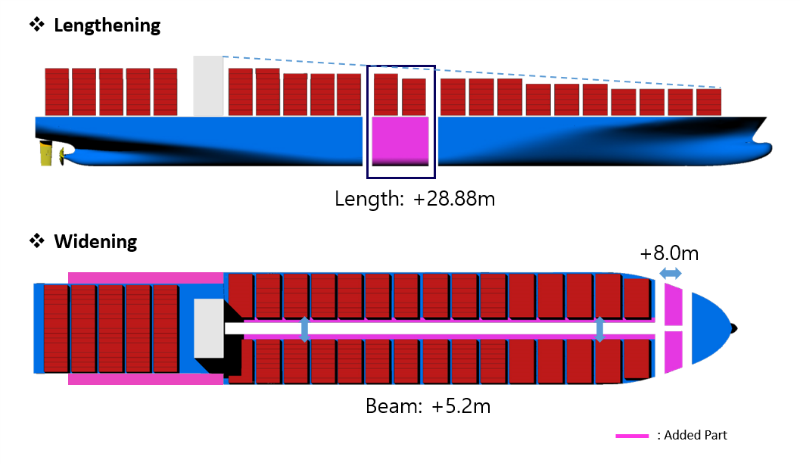

KR offered the shipping company two scenarios for the study. One was a traditional method, to increase the size of the vessel by lengthening the ship, while the other used a more recent approach, whereby the vessel’s breadth would be expanded, which was used by NSB group last year.

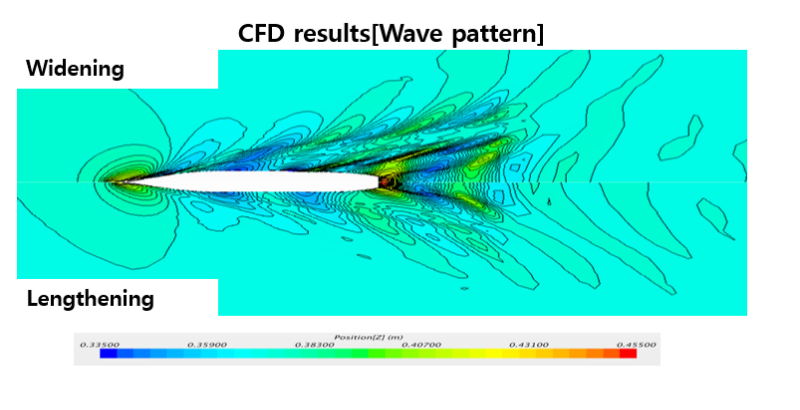

Using both of these methods, KR analyzed the new vessels potential speed, fuel efficiency, stability and strength, the cost and time needed for conversion, the size-expandability, the new vessels maneuverability and its anchoring.

Looking at the speed analysis, while both options showed a 4% drop after conversion, the length extension conversion was one knot faster than its width expansion counterpart. For fuel efficiency, the length extension conversion consumed 5% less than the alternative vessel.

In terms of stability and strength, the widening conversion showed improved stability, with almost no need for additional reinforcement to enhance the vessels strength. However, the lengthening scenario, the vessel stability was unaltered but it needed much more reinforcement on its deck and bottom parts to maintain its strength, because of the increased hull bending movement.

The study showed in general that the widening conversion would increase cargo carrying capacity by up to 30%, but in the lengthening scenario, capacity only increased by 15%.

It would take twice as long to make the changes to the widening conversion, compared to the time it would take to convert the vessel using the lengthening scenario. There would be no difference in the cost of conversion to either option, because the lengthening conversion requires more steel work. Lastly, the study found that the two options were almost the same in terms of maneuverability and anchoring.

Commenting the study, Dr. C. W. Kim, Executive Vice President, Technical Division of KR said:

“The cost to complete a ship conversion is only around 15% of the cost of a comparative newbuild and the conversion time required is considerably shorter. Therefore, it can be a great alternative to placing a newbuilding order. This study is just one of the ways KR works with its customers to evaluate different options to optimize their business profitability.